UC Berkeley unveils 3D-printed "Bloom" building made of powdered cement

Impression 3D ... sculpté (FAAST)

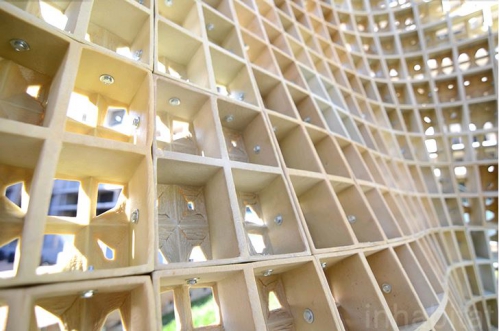

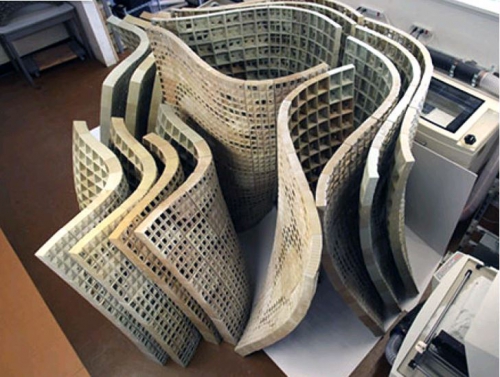

Ronald Rael and UC Berkeley's College of Environmental Design just unveiled the an innovative 3D printed building made from powdered cement. Measuring 9 feet high by 12 feet wide and 12 feet deep, the swirling Bloom pavilion is composed of 840 custom-printed blocks made from an iron oxide-free Portland cement polymer. The variegated bricks are printed with delicate floral patterns that allow natural light to shine into the pavilion's interior, and the building glows like a lantern when illuminated from within. UC Berkeley's College of Environmental Design calls it the "first and largest powder-based 3-D-printed cement structure built to date."

3D printing technology has advanced by leaps and bounds over the past decade. Whereas the first printers slowly churned out tiny trinkets and figurines, today’s advanced printers can produce functional tools, full-sized furniture, automobiles, and even entire buildings. Ronald Rael is pushing the technology to its limits, and the new Bloom pavilion opens up new possibilities for the field of 3D-printed architecture.

Rael is an associate professor of architecture at Berkeley’s College of Environmental Design and co-founder of Emerging Objects – a 3D printing think tank that recently developed a brick that can cool buildings using only water. He worked with Thailand-based Siam Research and Innovation and a graduate student research team composed of Kent Wilson, Alex Schofield, Sofia Anastassiou and Yina Dong to develop the elegant, curving structure made from 840 precisely printed bricks

The Bloom pavilion’s construction process and materials set it apart from from other 3D printed structures. Most 3D printed buildings are created by extruding wet cement through a nozzle. This process creates durable buildings, however the finished product is rough and imprecise. Bloom was constructed over the course of a year by 11 3D Systems printers using powdered cement, polymers, and fibers. This process minimized waste and yielded strong, lightweight bricks printed with high-resolution details. According to UC Berkeley, “Bloom is a precise 3-D-printed cement polymer structure that overcomes many of the previous limitations to 3-D-printed architecture. Such limitations include the speed and cost of production as well as aesthetics and practical applications.”

After its official unveiling yesterday, the Bloom Pavilion was disassembled and shipped to Siam Research and Innovation in Thailand to be displayed for several months before touring the world.

by Mike Chino, 03/09/15

http://inhabitat.com/worlds-largest-3d-printed-building-made-from-powdered-cement-unveiled-at-uc-berkeley/

Inscrivez-vous au blog

Soyez prévenu par email des prochaines mises à jour

Rejoignez les 16 autres membres